At Nano3Dprint, our passion is to connect those looking for electronic printing and 3D rapid prototyping functionality with the ability to bring their ideas to life. We do not exaggerate when we say that our groundbreaking 3D printing rapid prototyping technology is quickly transforming the field of printable electronics. But 3D printing of all kinds excites us, and with that in mind we thought we would share a bit of industry knowledge. Welcome to part two of our two-part series on bioprinting and its future uses and applications.

In our previous post, we defined bioprinting for our readers, which included the materials, processes, and methods that encompass this revolutionary 3D printing technique. In today’s post, we have the opportunity to continue to explore the world of bioprinting. Today’s piece will feature a more in-depth look (yet far from exhaustive we will warrant) at applications within bioprinting.

Each of the 3D bioprinting methods discussed in our previous post (extrusion, laser, microvalves, inkjet, and tissue fragment) have their pros and cons. And like we mentioned before, we could allocate each bioprinting method with its own post there is so much to say (say, that gives us an idea). But for the purposes of this series, let us say that some generalizations can be made about bioprinting techniques. Namely, researchers have been using scanners and 3D printers that have typically been employed to produce cars, model buildings, and prototype products, and are applying them to create real life human tissue. Let’s take a brief look at what some of the various research projects have been focused on all around the world.

Bone

Bone grafts are required by more than two million people across the world each year. The traditional method employed is to utilize a synthetic material in tandem with a subject’s bone. This method is lacking in that it fails to accurately imitate the naturally occurring bone and cartilage format. A second issue is that the synthetic material doesn’t allow for the growth and development of new tissue.

Swansea University

A research team from Wales has developed a solution that addresses the weaknesses in modern bone grafting. They’ve developed a method of 3D bioprinting that deposits an artificial bone matrix to replicate the exact shape of a given bone. The structure is designed to facilitate the regeneration of actual bone tissue by creating a structure for osteocyte cells to attach themselves to. It’s an ingenious approach to provide an environment for cell generation to flourish, essentially replicating the body’s natural processes. The research team out of Swansea discovered the importance of having the capacity to replicate the exact shape of a bone. The end result is implanted in the body of the subject. In around three months the “scaffolding” will disappear and only the newly grown bone will remain. Although still experimental at this stage, this 3D printing technique could revolutionize a field of medicine in dire need of improvement.

Internal Organs

Imagine a world that someone could get a freshly printed 3D heart transplant. Well, print this post out, put it in a time capsule, bury it, and dig it up in 10 years, and poof! Your dream is a reality. Researchers estimate that we are a minimum of ten years away from being able to bioprint fully functional complex internal organs like a heart or a kidney. But do not despair, because we can already print out less complex organs, such as the bladder. At Wake Forest University, scientists have been able to take cells from a subject’s dysfunctional bladder, and optimize it with stem cells and a structural framework. Next, researchers printed out a 3D mold and let the cultivated cells saturate its structure. Finally, the mould was placed in an incubator of sorts until it was deemed ready to be successfully transplanted into the patient’s vacant pelvis. Down the road, the mould broke down, leaving behind a fully-functional, brand-spanking-new bladder!

Livers, Kidneys, And Urethras, Oh My!

The Wake Forest University team has also accomplished a similar feat in being able to create and implant legitimate urethras. They did this using the same method as with the bladder transplant, with a blend of the subject’s cells and supplemental nutrients being seeded and sewn into the appropriate shape. Livers, on the other hand, pose more of a challenge. The best researchers have mustered up is a miniscule 3D printed functional liver (1 mm thick and 4 mm wide). But it only lived for 5 days. We hope you aren’t counting on a 3D bioprinted kidney anytime soon, because they have a wildly intricate cellular system designed for filtration. This has proven quite difficult to replicate. Hearts might turn out to be one of the most simplistic organs to replicate, in the sense that they are nowhere near as complex as a kidney or liver. The closest humanity has come is when a research team in the U.S. has made an “organoid”, which is a 3D printed, biological object with beating cardiac cells. Although it is”alive”, it doesn’t have the full range of functionality (durability, strength, nerves, blood vessels, connective tissue) that would make it a viable heart for someone. We are getting closer, though.

Skin

Skin grafts are used when someone’s skin becomes burnt to the point that healthy skin must be taken from the subject’s body and applied on the affected region. This generally works well, but often there isn’t enough undamaged skin to utilize. The same researchers at Wake Forest University (keep it up, gang) formulated a design to directly print skin cells onto burn wounds. A scanner is used to ascertain wound size and depth. This is significant because different types of skin cells can be found at different depths within the skin. The printer then applies layer upon layer of the appropriate cell type to cover the burn. Remarkably, a person only requires one-tenth the size of the burn in order to grow a sufficient amount of skin cells for skin printing. 3D printing and replicating skin cells is functional because skin is a layered organ, so the layered 3D printing technique coincides.

Cartilage

A team of researchers within the Department of Health Sciences and Technology at the institute for Biomechanics at ETH Zurich have been attempting to replicate human cartilage as a next step in 3D bioprinting. Using a mix of biopolymers and living cartilage cells from the lab’s bioprinter, the team has produced structures such as joint or nose cartilage, taking a mere 15 minutes to print. The ramifications in the field of reconstructive surgery are intriguing. Let’s do a for-instance. If a subject has their nose shattered in a car accident, a 3D reconstruction can be rendered on the computer while the subject undergoes a biopsy to derive cartilage cells from his or her own body. The cells are then spawned and mixed with the biopolymer, which serves as the mould. After a few months, the biopolymer will be broken down by the new cartilage itself, until all that remains is an organic nose.

Conclusion

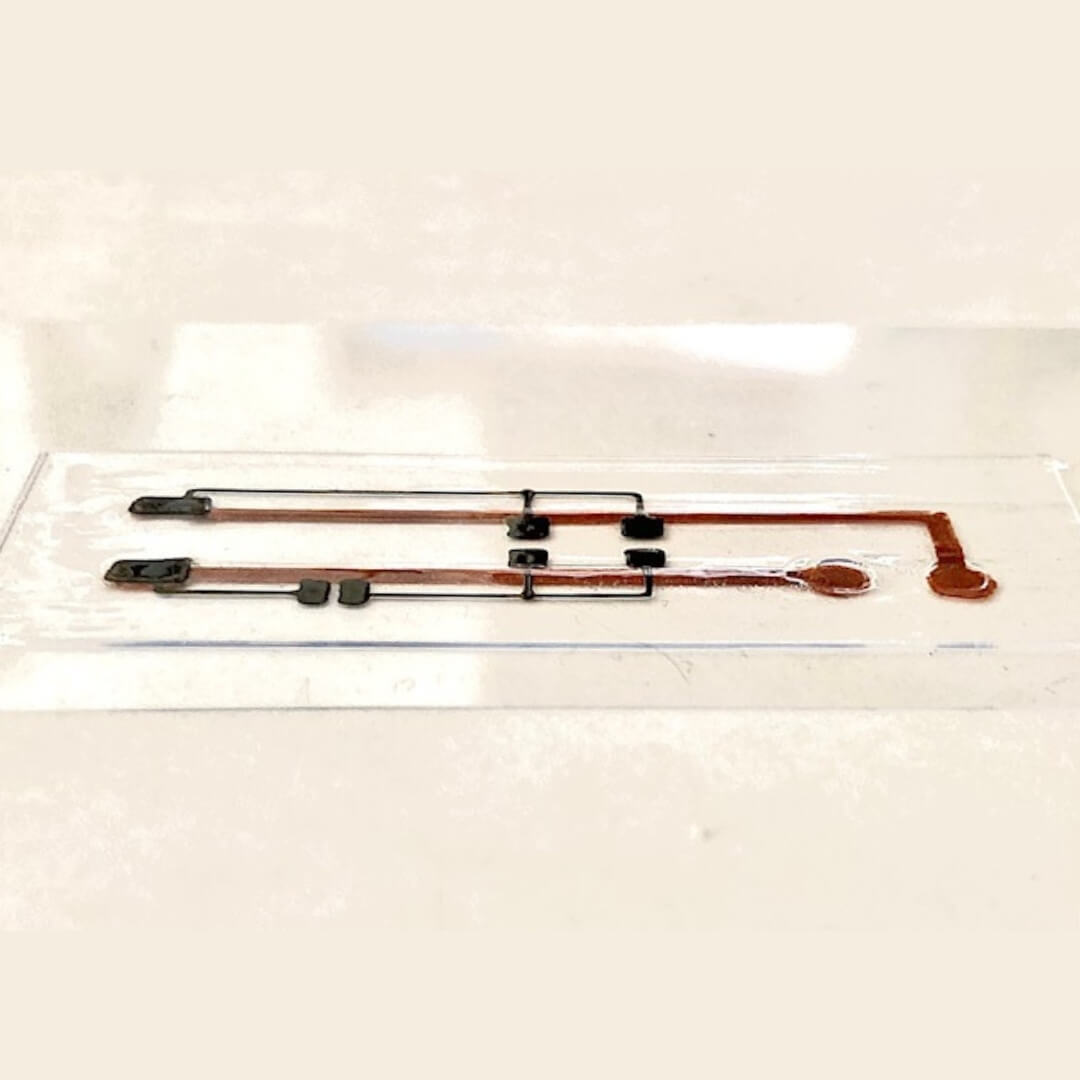

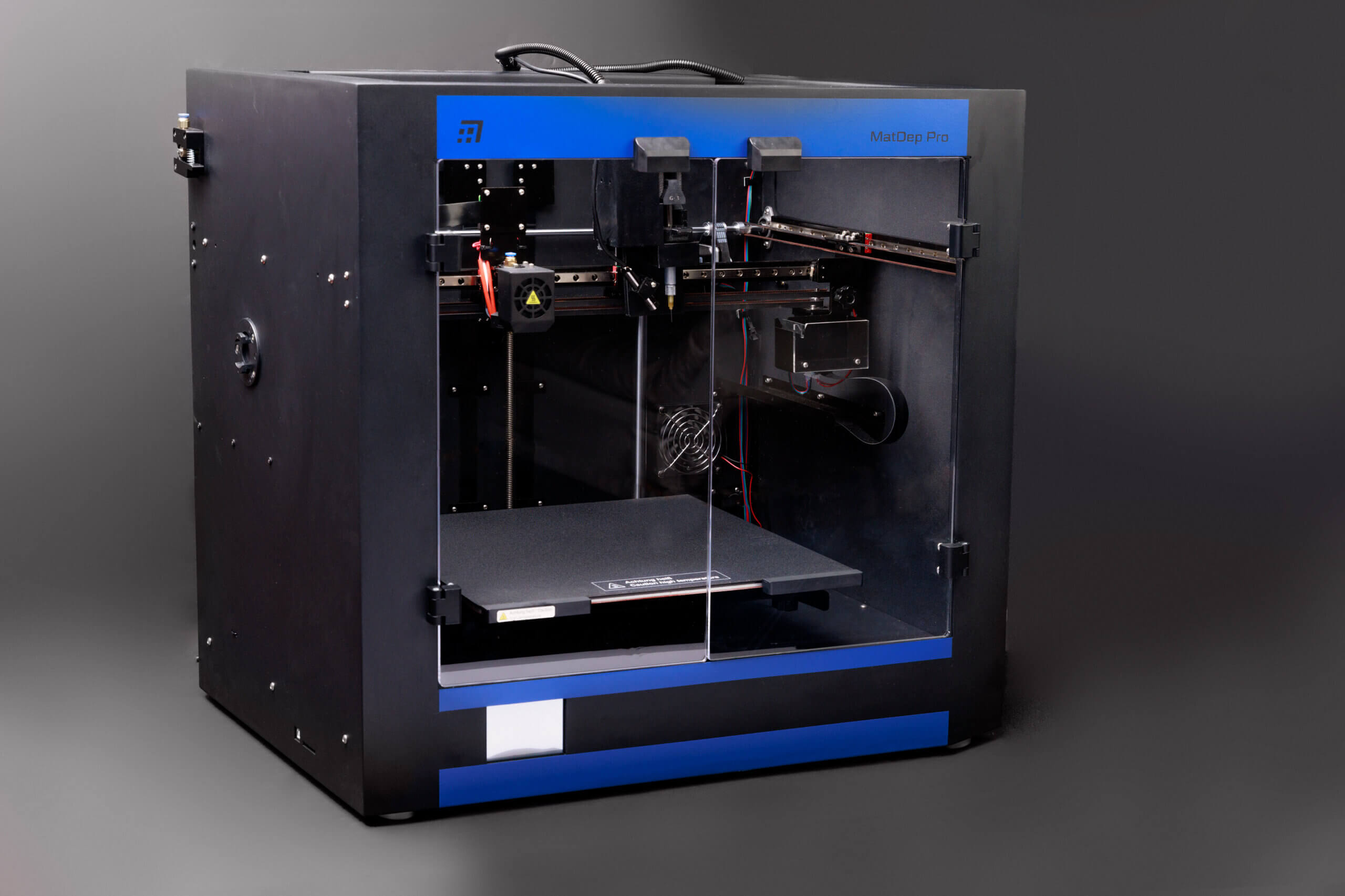

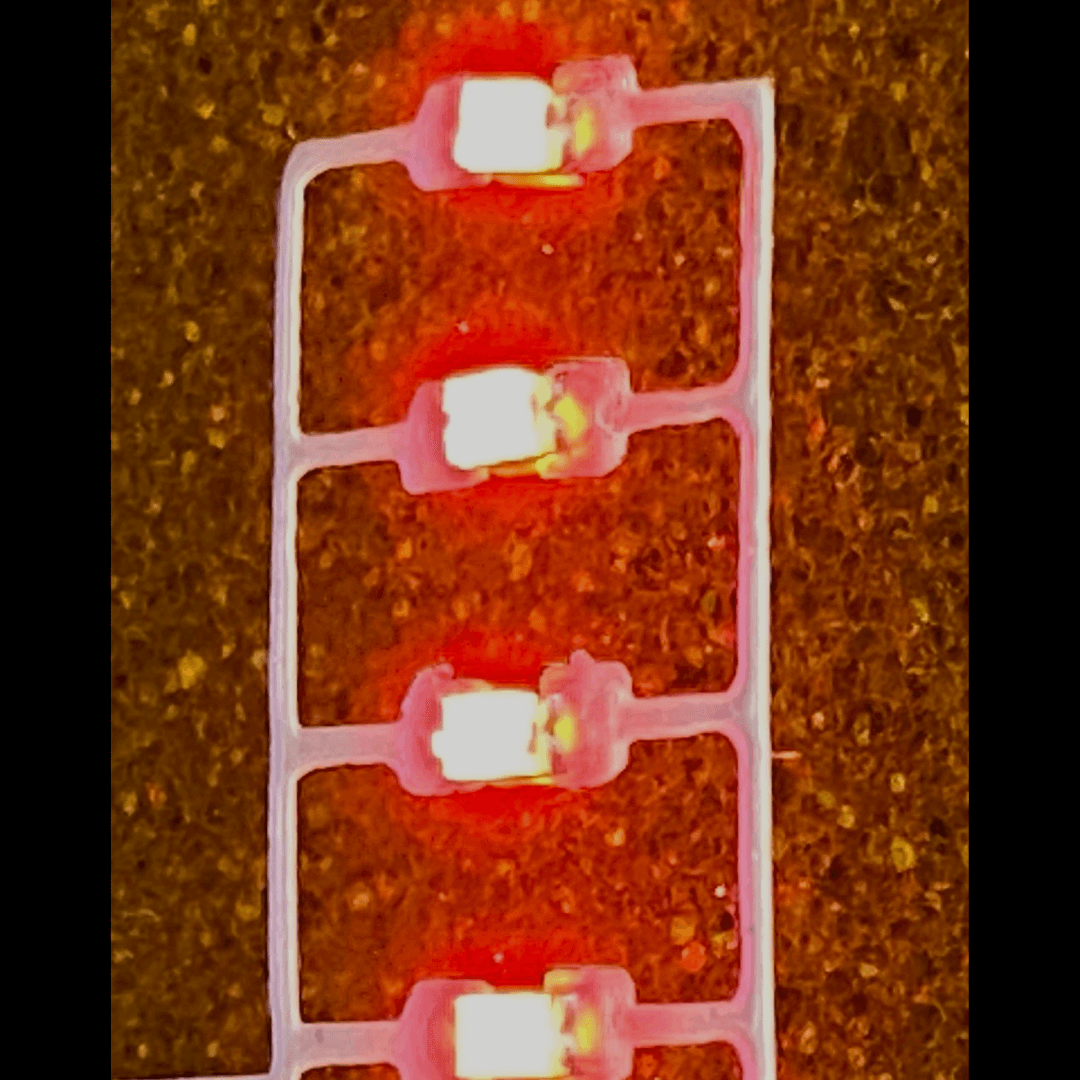

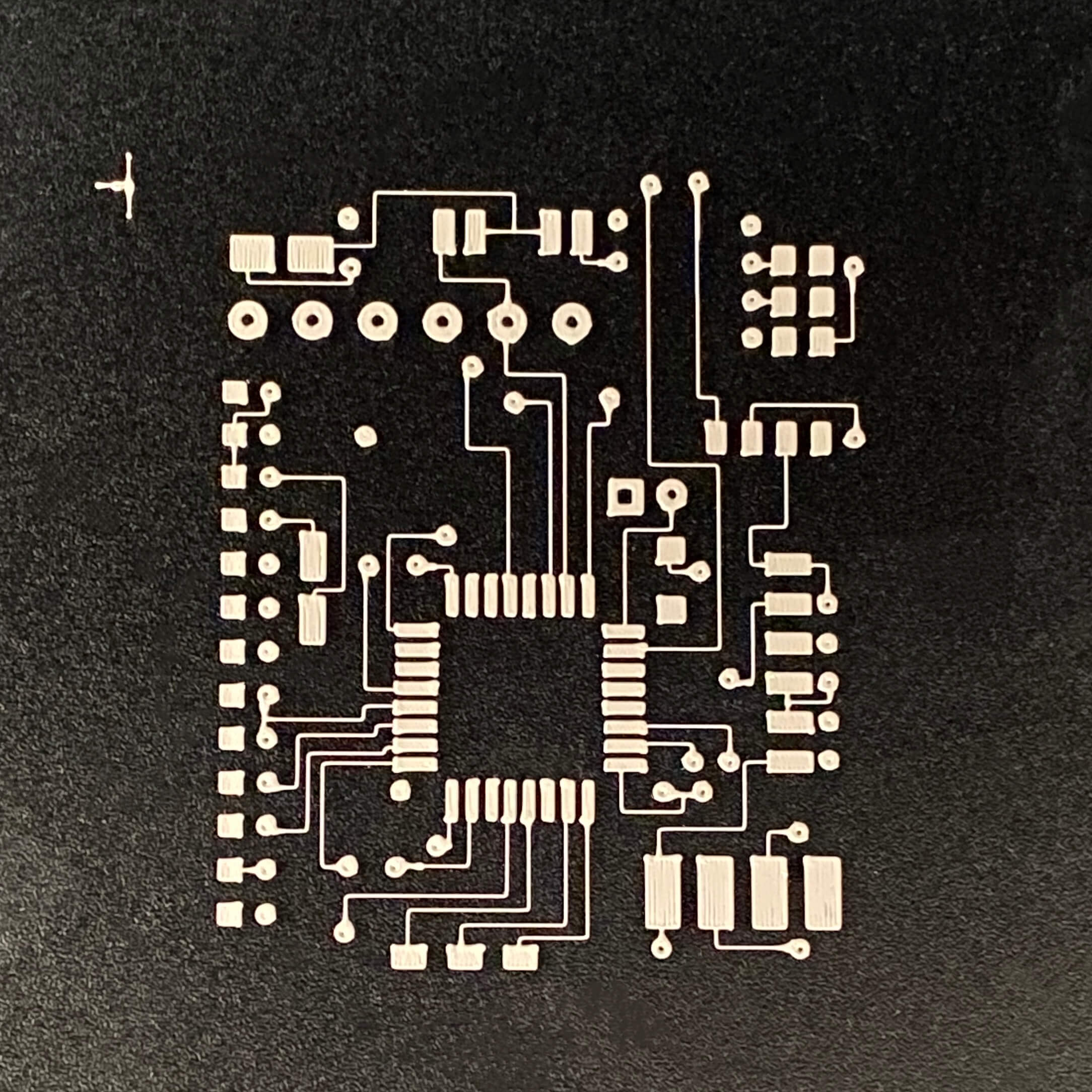

We are going to have to be patient, but the signs are encouraging. At the end of the day, researchers have made incredible progress in just the past ten years, but still have a long way to go to reach the full potential that bioprinting has to offer. The fact of the matter is that human organs are dramatically more complex than ceramic toys or even printable electronics. We will simply need to wait. One thing we will not have to wait for, however, is the aforementioned printable electronics. In terms of the here and now, Nano3Dprint has advanced printers fully capable of using functional inks. This means that printable electronics can be available to inventors, professors, and really anyone, in just a matter of minutes. Check out our full line of printers ready to be used for 3D rapid prototyping and electronic printing. What could you make?