Wired for Success: Five Advantages of 3D Printing Wires into Your Functional Design

Printed electronics is one of the most rapidly growing markets in the field of 3D printing today. Maybe you’ve thought about trying to 3D print your ideas, but were limited by basic technology that couldn’t produce wires or functional objects with embedded circuitry. At nano3Dprint we say, “Don’t manually add wires to your designs – 3D print them!”

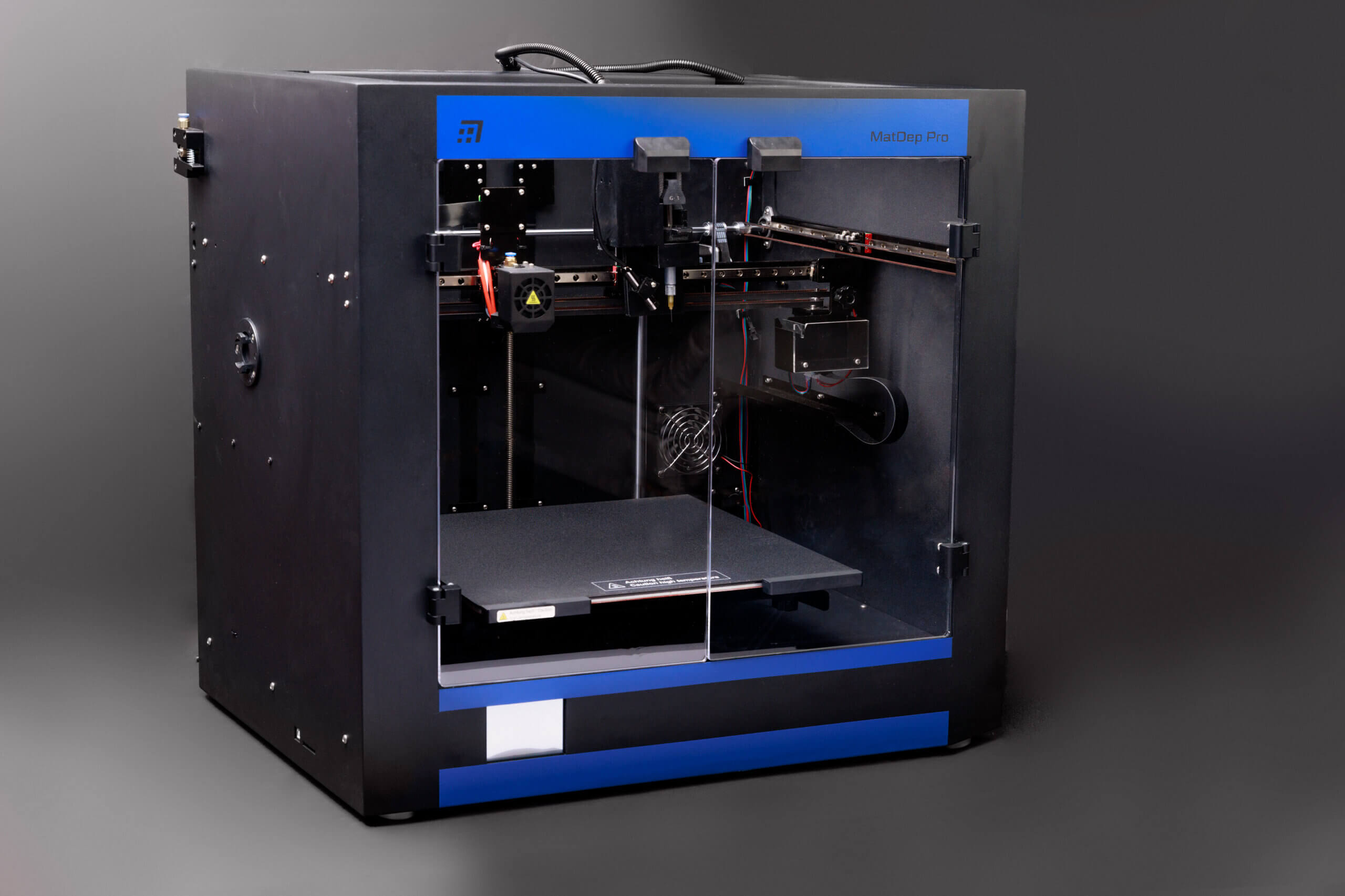

3D printing wires in advanced applications and printed electronics saves time and money, and yields compact conformal designs. It enables you to seamlessly integrate sensors, actuators, and circuits into larger prints. You may be wondering how to add wires into 3D prints, and the good news is that it can easily be achieved with nano3Dprint’s A2200 3D Multi-material Electronics Printer and B3300 Dual-Dispensing 3D Printer. Both direct-write systems have two print heads; one for the build material and one to 3D print ‘wires’ made with conductive inks and pastes.

Here are five reasons why 3D printing wires is a total game-changer:

- Produce Novel Form Factor Functional Prints

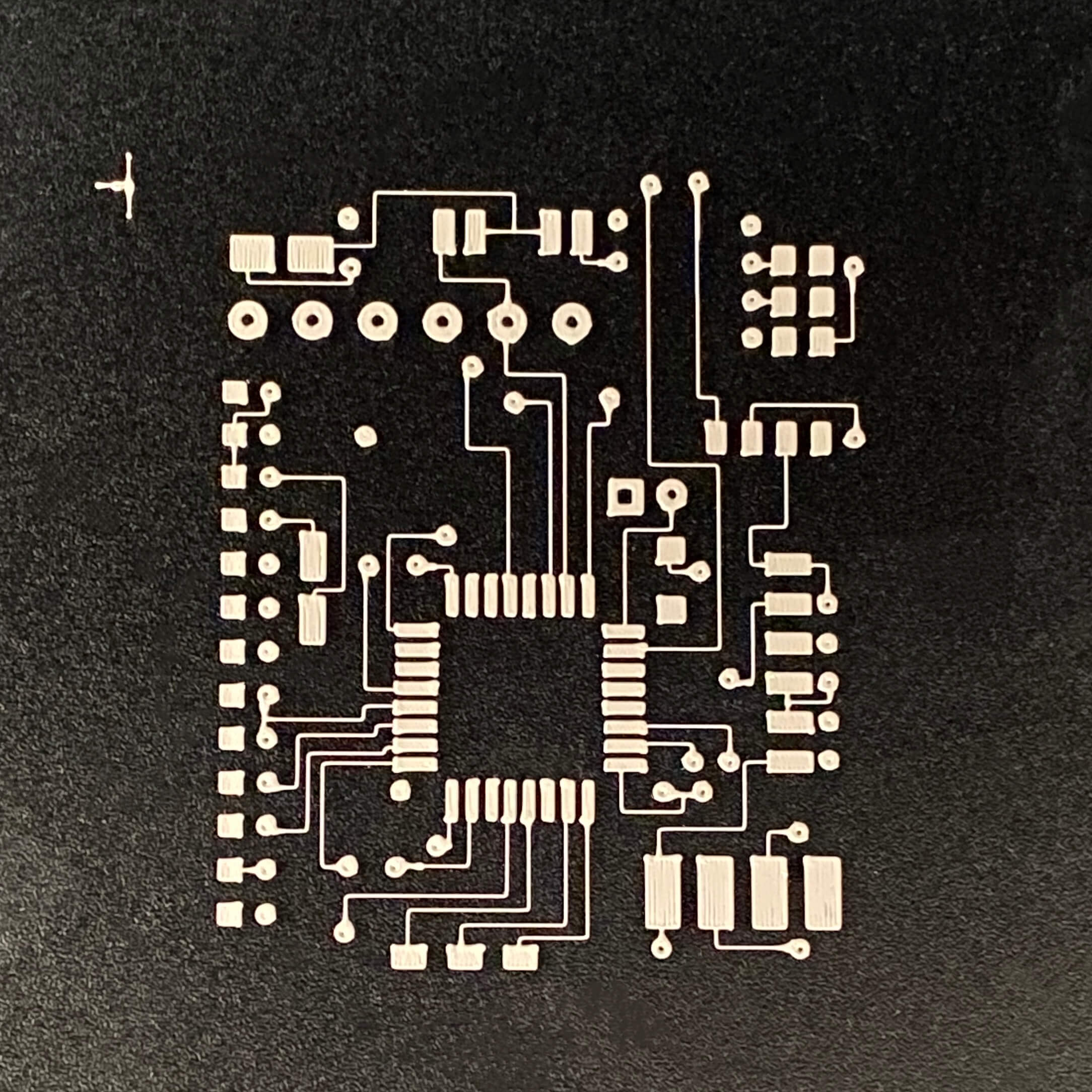

Embed interconnects into the structural member of the design, such as the arm of a drone. Add wires to the leg of a robot! An advantage of 3D printing your interconnects is the ability to print the wires directly into the design’s internal structure, resulting in sleeker designs and novel form factors that can’t be achieved through injection molding, stamping, or traditional wiring methods.

- 3D Printing Wires Allow for More Complex and Conformal Features in Your Final Designs

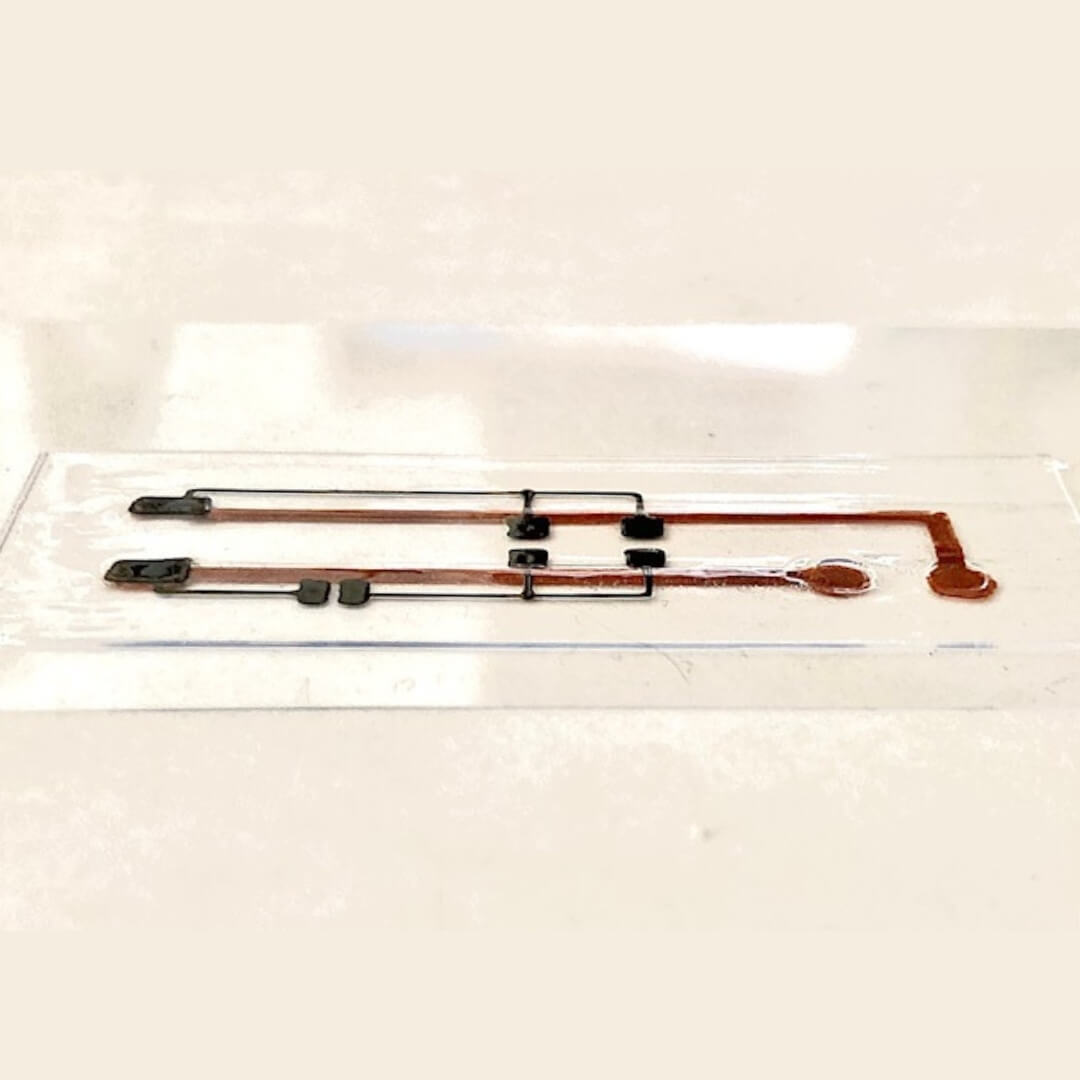

When it comes to electronics and advanced applications, the tinier they are, the better. Small electronics are what the future is made of. By 3D printing wires in your prototypes, spare parts,and final products, you can create complex and intricate geometries that are hard to achieve in any other fashion. Plus, there’s no need to add extra weight or space to the design with special housing to hold wires. With nano3Dprint’s A2200 and B3300, you can place conductive lines exactly where you need them and print down to 0.20mm trace and space width.

- 3D Printing Wires is Easier and More Accurate Than Adding Wires by Hand

It takes effort to place wires into 3D structures manually, and there’s always a chance for human error. When you 3D print conductive lines, you can achieve higher accuracy, decrease your workload, and skip unnecessary steps.

- It’s Faster To 3D Print Wires

In this day and age, rapid prototyping is essential. When you 3D print wires, you don’t have to stop what you’re doing, take your design out of your 3D printer, break out your tool set, and go through the painstaking process of adding wires manually. Printing wires saves you time and energy.

- 3D Print Wires with a Variety of Materials

Gold, Silver, Copper – what type of wires will you 3D print? The A2200 and B3300 can print any NovaCentrix inks, Sigma Aldrich inks and almost any material with viscosity lower than 54000 mPa·s. You can even use your own inks! higher viscosity inks result in significantly higher layer heights than low viscosity inkjet type inks. Higher-viscosity materials also produce more conductive traces since they have a higher volume of nanoparticles. The conductivity, relative to copper, is 30% +/-5%. And as an added bonus, these conductive particles can have sensing capabilities, provide semiconducting properties, and behave as a dielectric.

- BONUS: Reduce Costs by 3D Printing Wires

We couldn’t stop for just five reasons why 3D printing wires is the best way to go. It’s also economical! When you 3D print wires, you can bypass the need for additional tooling, third-party help, and human labor. It minimizes the amount of components needed to get the job done.

With nano3Dprint, you can engineer small flexible wearables, medical devices, Drones and Robotics with embedded circuitry. For thin film devices printed with functional pastes and inks such as Au, Ag, Cu, resin, silicone, graphene solutions, and beyond, we recommend the B3300, which can print these materials side-by-side. If you want to produce fully 3D printed devices with embedded electronics and specialized applications with FDM (PLA, ABS, etc.), we suggest using nano3Dprint’s A2200. The A2200 prints plastic side-by-side with the same functional inks and pastes that the B3300 uses.

We hope you enjoy streamlining your 3D printing process, reducing your workload, and producing bite-sized tech with 3D printed wires.

Would you like help deciding which 3D printer is right for you? Drop us a line at info@nano3dprint.com and tell us about your application. We’ll help direct you to the best solution for your electronics 3D printing needs.