In our previous articles, we’ve taken a look at a range of topics which have to do with 3D manufacturing, the 3D printing process, and all sorts of topics which relate to this rapidly developing field. We’ve discussed the democratization of 3D printing, how honey bees are the original 3d printers, how 3D printers are early versions of Star Trek’s “replicators” in terms of food production, and other fun explorations.

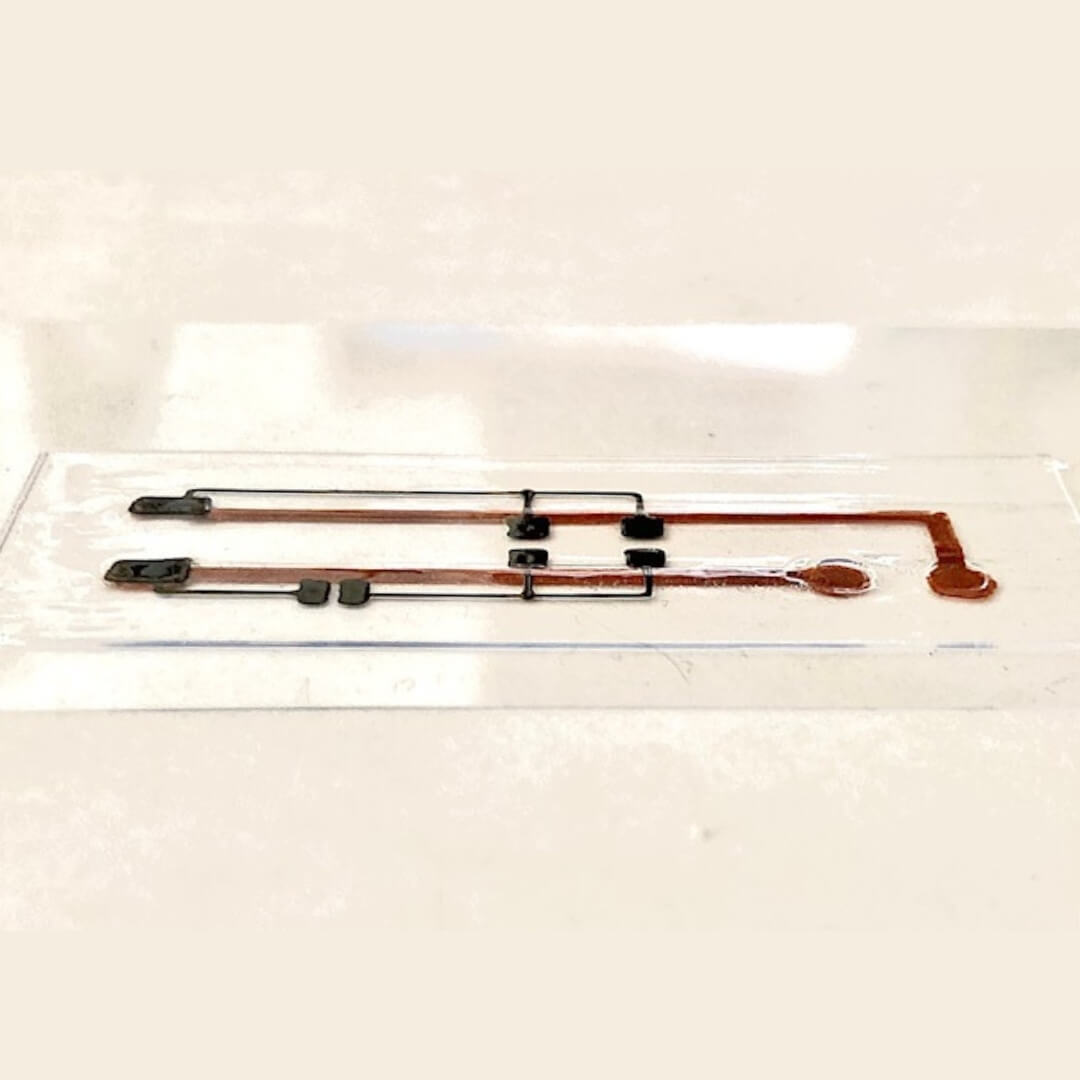

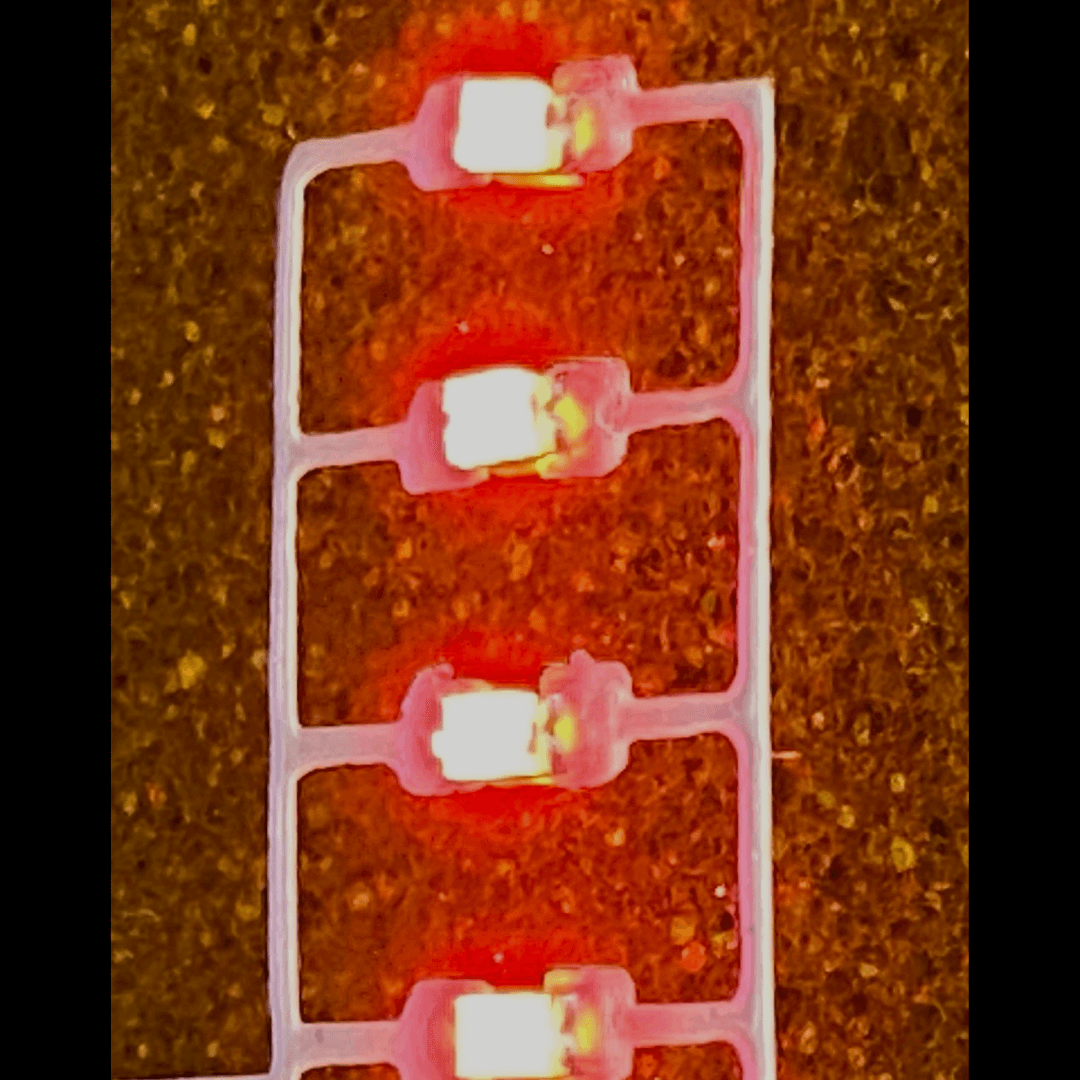

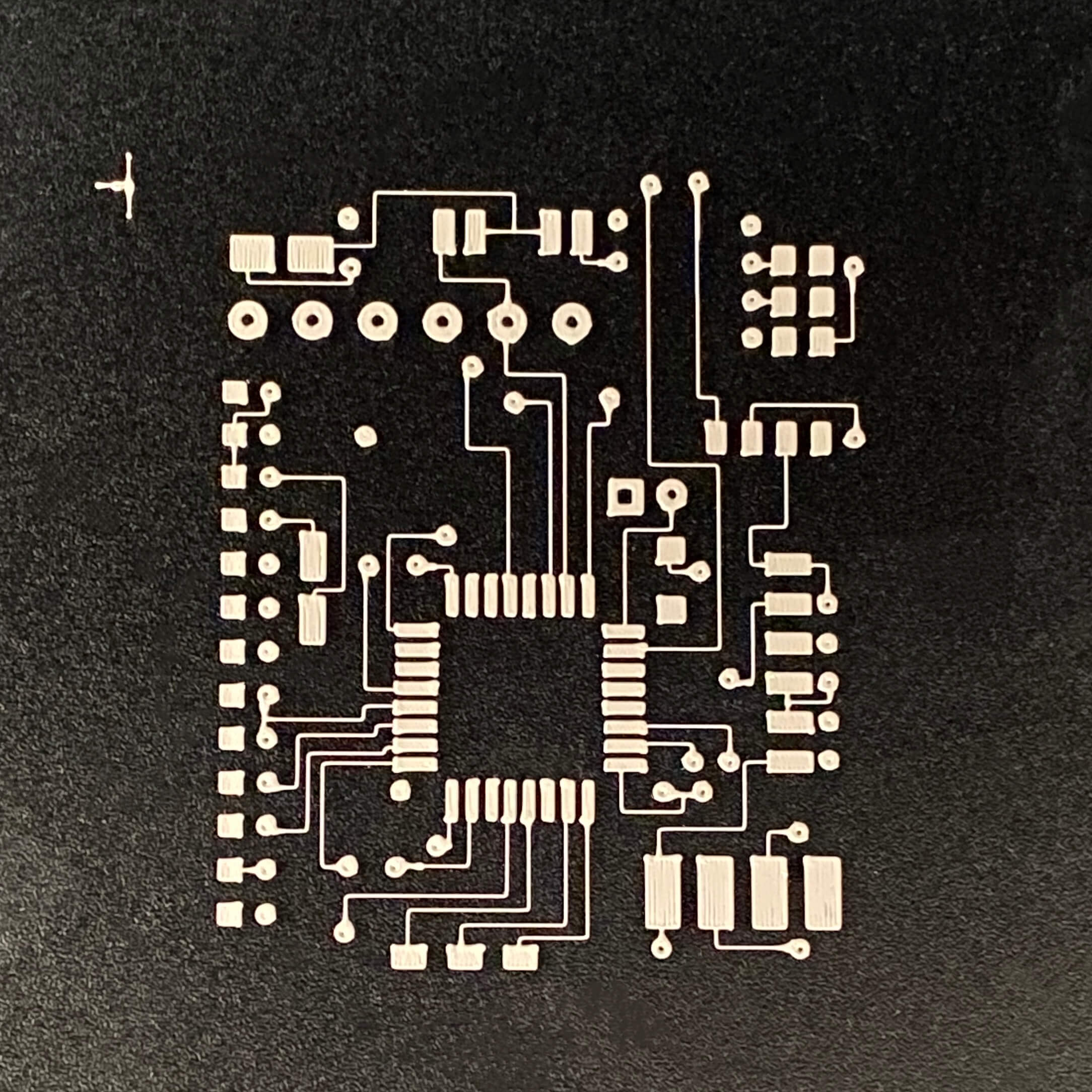

We’ve also taken brief forays into 3D printing and the automotive industry, bio printing human organs, and even discussed our own speciality here at Nano3Dprint – our groundbreaking 3D printing rapid prototyping technology on the micro and nano scales. With applications in printable electronics and beyond, Nano3Dprint is on the cutting edge, providing private engineers and other researchers the opportunity to see their unveiled plans take shape.

In today’s post, we are going to talk a little bit about our 3D printing company, and a lot about the industry as a whole. Specifically, we will highlight a few of the more common myths, or at least questions, associated with the field. If you are interested in learning about what some of the limitations on 3D manufacturing are, among a few other interesting topics, then read on! This post is for you.

Myth: You Can Only Print Plastic Items

While this may have been the case 10 or 15 years ago, 3D printing technology has evolved monumentally since then, and these days it’s common practice to print metals, resins, bio-materials (although that can get steep), wood, and carbon fiber. While it can be steep, it doesn’t cost an arm and a leg. The real issue has less to do with a printer’s functionality to handle new types of material, but rather the entire process is contingent upon filament technology. Electronic printing and bioprinting can both point to dramatic progress in our understanding and implementation of novel filament technology, which includes bioprinting with stem cells.

Myth: 3D Printers Mass Produce Guns

While 3D printers can produce plastic guns, you have to have the CAD file of a handgun to create it. There is no gun button on any 3D printer. That said, although rare, it is a serious prospect which should be treated cautiously, especially by any nation that has strict gun regulations. However, with most all printed guns being made out of plastic, such plastic guns will only fire a live bullet once or twice before falling apart. That isn’t to say that gun control and 3D printing shouldn’t be taken seriously, but rather that it isn’t a viable solution to a group of people looking to arm themselves in a serious way.

Myth: The 3D Printing Industry Has Already Peaked

Some people mistakenly believe this. Once said by Dallas Maverick’s owner and venture capitalist Mark Cuban to be a future 1 trillion dollar industry, more recent estimates are closer to the 20 trillion dollar figure. The reason for this huge spike has a lot to do with the variety of fields in which 3D rapid prototyping and manufacturing can have an affect.

The key point here is that 3D printing, specifically in reference to printable electronics, has a consolidating influence on any object. For example, future (and some current) automobiles will be equipped with advanced computers within the very framework of the vehicle, which could include the door or floor.

In the medical field, while we aren’t yet able to fully print any time of organ, the progress recent research teams have made is extremely encouraging. In the world of organ replacements and prosthetics, there are exciting possibilities.

Myth: 3D Printing Isn’t Available To The Public

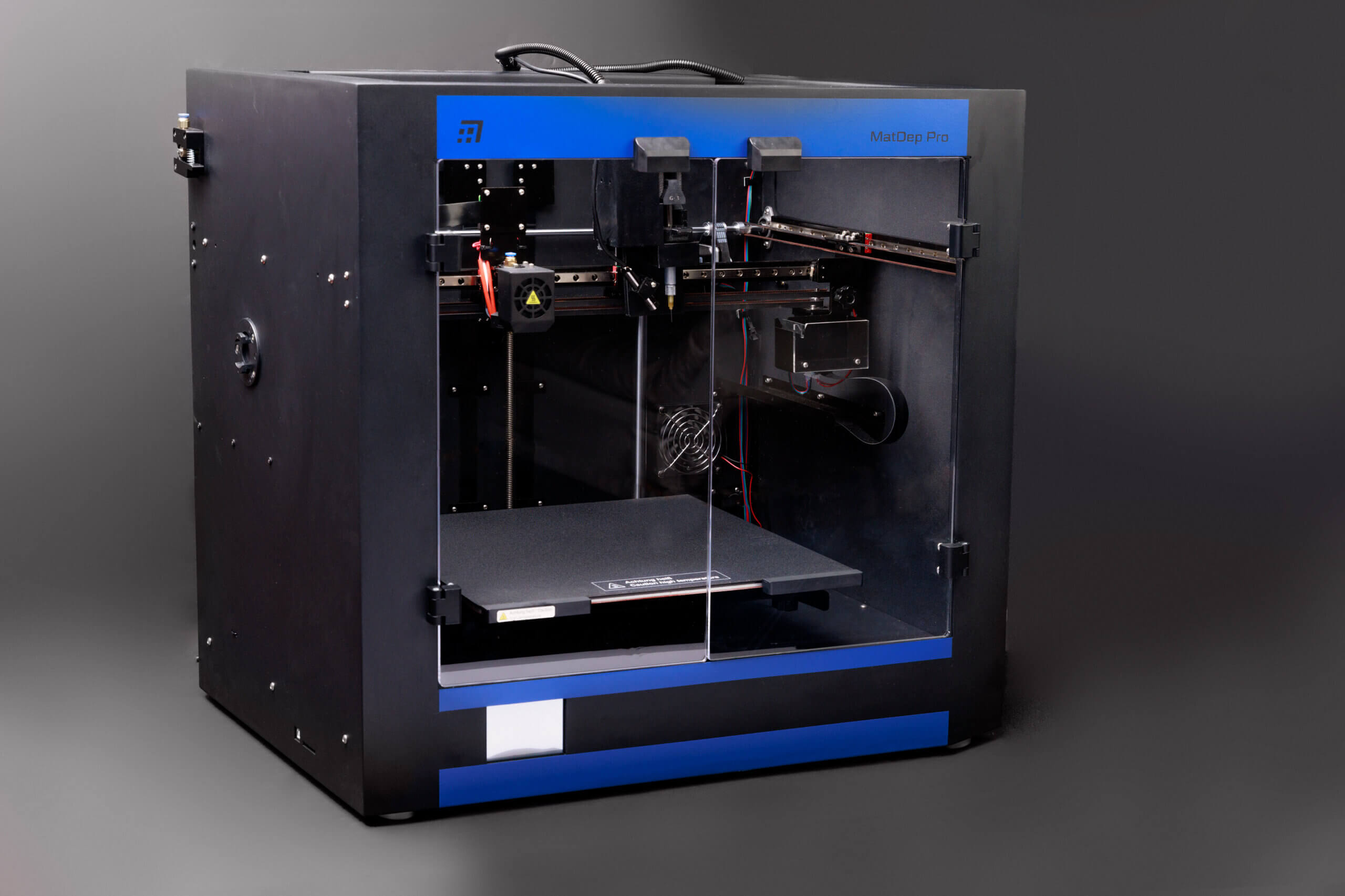

This is, if you’ll allow the expression, patently false. Take our own top 3D printers, for instance. Our mission at Nano3Dprint is to provide engineers, teachers, and private researches with the ability to leverage our nano and micro technology into industrial, R&D, printable electronics and other applications. We exist to democratize inventorship, and we have accomplished that goal by essentially lowering the barrier for prototyping and small volume 3D production of fully functional printable electronic devices. That’s why we say the rapid prototyping possibilities are endless.

But beyond our own 3D printer providing company, while there are a variety of 3D printing companies dedicated to their respective fields, it has yet to be applied at the individual, consumer level. We are still a ways away from a 3D printer being found in every home. But it is far from absurd to consider the possibility that you might be able to order a kitchen utensil online, only to have it printed in a matter of minutes by your personal 3D printer! Other, more advanced functionalities, like 3D printing food or organs, are far, far away from becoming a reality.

All 3D Printers Are Expensive

Untrue. Allow us the opportunity one more time to highlight our own 3D printer company. We at Nano3Dprint offer affordable options on printed electronics 3D printers. For example, our A1100 model is just under $3,000, is designed for 3D printable nanomaterials with the use of proprietary functional materials. With a hardened nozzle, proprietary nano filament (our own special blend), and optimized dual extruders, this 3D printer represents great value while still maintaining its innovation in performance.

Printing Buildings: China And The 3D Printed Houses

Yes, China actually did (partially) print entire houses recently. While we at Nano3Dprint specialize in the nano and micro levels of the field, others focus on large scales…very large scales. In this case, the filament is no longer plastic or metal, but cement. With that in mind, the large scale, layer-by-layer cement laying is pretty far removed from the rest of the 3D printing world. So while it qualifies under the same umbrella of nomenclature, one has very little to do with the other aside from both being being layer by layer.

3D Manufacturing Food

As we discussed in a previous post, 3D printing food is one of the most interesting applications of 3D prototyping and printing. Reports on flavor and texture leave a lot to be desired more often than not, but hey, Rome wasn’t built in a day, so give it a little bit of time before throwing the baby out with the bath water. That being said, this 3D printing food can be considered more of a novelty than a viable economic branch of 3D printing.

Nano3DPrint 3D Print Service

Here’s another myth for you; Nano3Dprint only provides innovative 3D printers. While it is true that we do have some of the most advanced 3D printers you will find for any price, our scope goes beyond simply selling 3D printers. We love teaming up with inventors and researchers who are in need of our services. So if want your design 3D printed, want to customize a unique gift, or have another reason for a one time use, consider Nano3Dprint. All you need is a compatible file of your design. And if you want some experienced eyes on your project, we are happy to provide consultative services sas well. Feel free to contact us directly at info@nano3Dprint.com

Get In Touch With Us Today!

We hope that you’ve enjoyed this quick look into what 3D printing both is and isn’t. We have a passion to educate and assist those in this community. If you are interested in taking advantage of this unique opportunity to own your own 3D printer, which will open you up to a world of new possibilities, get in touch with us at Nano3Dprint today. We have a passion for helping your dreams take shape.